-

Details

-

Category: Image Measuring Instrument

IMI-TOP series, The whole machine granite structure design, better performance, longer life, a new

generation of humanized measurement software, stronger functions and higher precision, precision

optical measuring instruments made with the combination of precision mechanics, electronics, and

optical measuring systems.

Best suitable for precision manufacturing industries such as the following: Molding, machining parts,

tools, screws, gears, automobiles, watches, machines, aerospace parts, semi-conductor, rubber, plastic,

auto lathe machining, precision spring, and etc.

IMI-TOP series is great for design & development, QC inspections, and educational purpose in schools.

IMI-TOP series is design specifically to measure length, angles, radius, points, line, circle, distance, and

other 2D/3D geometric element measuring requirements. Magnified projection image for inspection and

comparison of the workpiece contour and surface shape.

OIMI-TOP series machine structure are made with combination of precision granite parts, linear or roller

bearings slide, high precision linear scale, high resolution lens, color camera, image measuring software.

The exceptional quality is your number 1 choice for workshop inspection and QC department examination.

| Model No. |

Measuring Range (XY) |

| IMI-AF200 |

200*100*150mm |

| IMI-AF300 |

300*200*150mm |

| IMI-AF400 |

400*300*200mm |

| IMI-AF500 |

500*400*200mm |

*Z axis height can be customized according

to requirements

Technical Specifications

| Resolution : |

0.001mm/0.00005” (X-Y-Z axis high accuracy linear scale) |

| Measuring Accuracy : |

±(3+L/200) μm (X, Y Axis) |

| Main structure: |

XY-axis DIN 00 grade granite measuring table & Z axis arm type granite column |

| Transmission system: |

3-axis cross linear ball slide and toothless screw drive module |

| Electronic system: |

Z-axis AC servo motor speed control system and controller |

| Image system: |

1/3” 0.41M pixels high resolution CCD color camera |

| Image magnification: |

25X-250X |

| Focus system: |

Z axis electric motor & software autofocus system |

| Optical system: |

0.7-4.5X continuous zoom ultra-low distortion optic lens. |

| Illumination system: |

High brightness adjustable LED surface and transmission parallel light |

| Computer system: |

Computer with 21.5”LCD color monitor, keyboard, mouse |

| Software system: |

Jingstone Metrology 2.5D image measuring system. |

| Measuring result output: |

Word, Excel, TXT, DXF, SPC |

| Standard Accessories: |

Calibration plate, measurement software, dongle, operation manual |

| Optional Accessories: |

Steel instrument working table cover with OA desktop |

-

Details

-

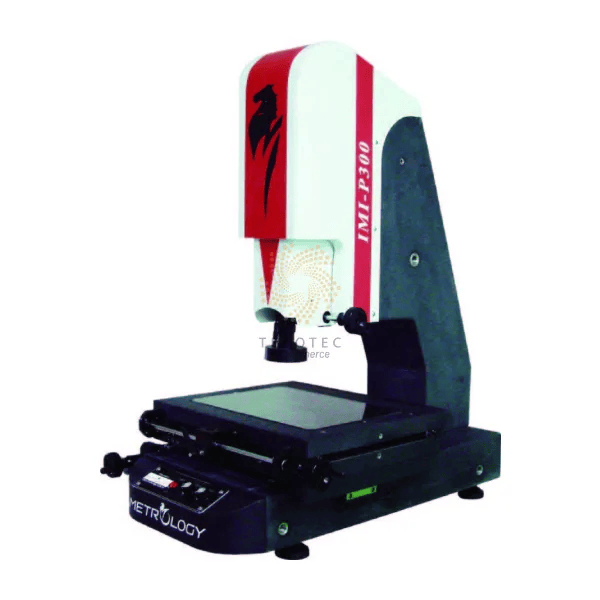

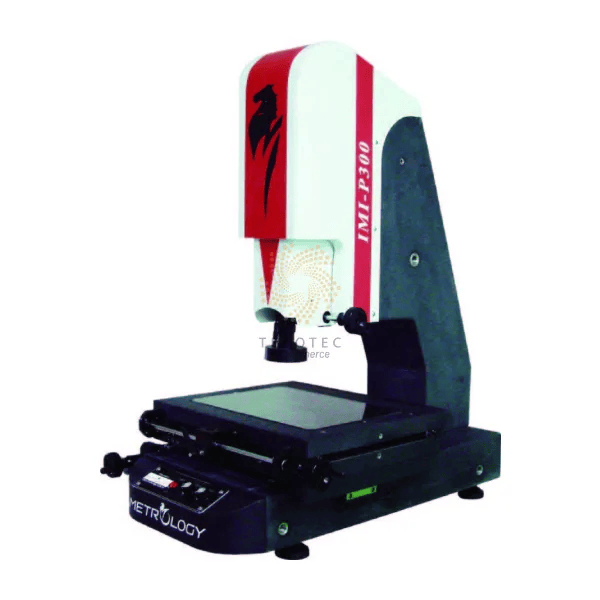

Category: Image Measuring Instrument

IMI-TOP series, The whole machine granite structure design, better performance, longer life, a new

generation of humanized measurement software, stronger functions and higher precision, precision

optical measuring instruments made with the combination of precision mechanics, electronics, and

optical measuring systems.

Best suitable for precision manufacturing industries such as the following: Molding, machining parts,

tools, screws, gears, automobiles, watches, machines, aerospace parts, semi-conductor, rubber, plastic,

auto lathe machining, precision spring, and etc.

IMI-TOP series is great for design & development, QC inspections, and educational purpose in schools.

IMI-TOP series is design specifically to measure length, angles, radius, points, line, circle, distance, and

other 2D/3D geometric element measuring requirements. Magnified projection image for inspection and

comparison of the workpiece contour and surface shape.

OIMI-TOP series machine structure are made with combination of precision granite parts, linear or roller

bearings slide, high precision linear scale, high resolution lens, color camera, image measuring software.

The exceptional quality is your number 1 choice for workshop inspection and QC department examination.

| Model No. |

Measuring Range (XY) |

| IMI-P200 |

200*100*150mm |

| IMI-P300 |

300*200*150mm |

| IMI-P400 |

400*300*200mm |

| IMI-P500 |

500*400*200mm |

*Z axis height can be customized according

to requirements

Technical Specifications

| Resolution : |

0.001mm/0.00005” (X-Y-Z axis high accuracy linear scale) |

| Measuring Accuracy : |

±(3+L/200) μm (X, Y Axis) |

| Main structure: |

XY-axis DIN 00 grade granite measuring table & Z axis arm type granite column |

| Transmission system: |

3-axis cross linear ball slide and toothless screw drive module |

| Image system: |

1/3” 0.41M pixels high resolution CCD color camera |

| Image magnification: |

25X-250X |

| Focusing device: |

Z-axis transmission module handwheel, manual adjustment of image focus |

| Optical system: |

0.7-4.5X continuous zoom ultra-low distortion optic lens. |

| Illumination system: |

High brightness adjustable LED surface and transmission parallel light |

| Computer system: |

Computer with 21.5”LCD color monitor, keyboard, mouse |

| Software system: |

Jingstone Metrology 2.5D image measuring system. |

| Measuring result output: |

Word, Excel, TXT, DXF, SPC |

| Standard Accessories: |

Calibration plate, measurement software, dongle, operation manual |

| Optional Accessories: |

Steel instrument working table cover with OA desktop |

-

Details

-

Category: Image Measuring Instrument

IMI-TOP series, The whole machine granite structure design, better performance, longer life, a new

generation of humanized measurement software, stronger functions and higher precision, precision

optical measuring instruments made with the combination of precision mechanics, electronics, and

optical measuring systems.

Best suitable for precision manufacturing industries such as the following: Molding, machining parts,

tools, screws, gears, automobiles, watches, machines, aerospace parts, semi-conductor, rubber, plastic,

auto lathe machining, precision spring, and etc.

IMI-TOP series is great for design & development, QC inspections, and educational purpose in schools.

IMI-TOP series is design specifically to measure length, angles, radius, points, line, circle, distance, and

other 2D/3D geometric element measuring requirements. Magnified projection image for inspection and

comparison of the workpiece contour and surface shape.

OIMI-TOP series machine structure are made with combination of precision granite parts, linear or roller

bearings slide, high precision linear scale, high resolution lens, color camera, image measuring software.

The exceptional quality is your number 1 choice for workshop inspection and QC department examination.

| Model No. |

Measuring Range (XY) |

| IMI-T100 |

100*100mm |

| IMI-T200 |

200*100mm |

Technical Specifications

| Resolution : |

0.001mm/0.00005” (X-Y axis high accuracy linear scale) |

| Measuring Accuracy : |

±(3+L/200) μm (X, Y Axis) |

| Main structure: |

Granite base, 2D measurement software, 360° rotating table (IMI-T100)

Metal base & body, 2D measurement software (IMI-T200) |

| Transmission system: |

2-axis cross linear ball slide and toothless screw drive module |

| Image system: |

1/3” 0.41M pixels high resolution CCD color camera |

| Image magnification: |

25X-250X, Z-axis adjustable focusing distance 90mm |

| Focusing device: |

Z-axis manual transmission module handwheel, 75mm adjustment of focus |

| Optical system: |

0.7-4.5X continuous zoom ultra-low distortion optic lens. |

| Illumination system: |

High brightness adjustable LED surface and transmission parallel light |

| Computer system: |

Computer with 21.5”LCD color monitor, keyboard, mouse |

| Software system: |

Jingstone Metrology 2.5D image measuring system. |

| Measuring result output: |

Word, Excel, TXT, DXF, SPC |

| Standard Accessories: |

calibration plate, measurement software, dongle, operation manual |