| Model No. | Measuring Range (XY) |

|---|---|

| IMI-CNC600 | 600*500*200mm |

| IMI-CNC800 | 800*600*200mm |

| IMI-CNC1000 | 800*1000*200mm |

| IMI-CNC1200 | 1000*1200*200mm |

| IMI-CNC1500 | 1000*1500*200mm |

| IMI-CNC2000 | 1500*2000*200mm |

*Z axis height can be customized according to requirements

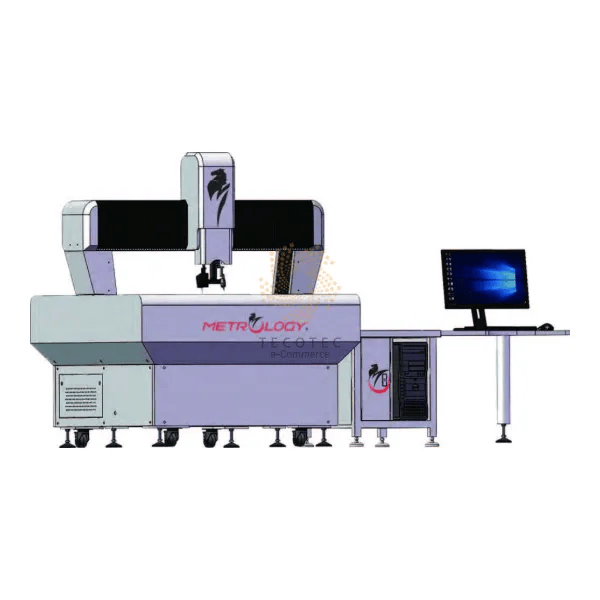

Technical Specifications

| Resolution : | 0.0005mm/0.00002” (X-Y-Z axis high accuracy linear scale) |

|---|---|

| Measuring Accuracy : | ±(3.5+L/200) μm (X, Y Axis) |

| Main structure: | DIN 00 grade XZ axis bridge type granite column & Y-axis measuring stand |

| Transmission system: | 3-axis high precision linear slide & ball screw drive module |

| Control system: | CNC automatic editing program measurement and 3-axis joystick controller |

| Electronic system: | 3-axis smart control servo motor and integrated motion control card |

| Image system: | Gigabit network high resolution million pixel color industrial camera |

| Image magnification: | 25X-250X |

| Optical system: | 0.7-4.5X continuous zoom ultra-low distortion optic lens. |

| Focus system: | Z axis electric motor & software autofocus system |

| Illumination system: | Programmable surface light source with four rings and eight sections |

| Probe system: | Renishaw (U.K.) MCP touch trigger probe, setting ring and ruby tips. |

| Computer system: | Quad core computer with 21.5”LCD color monitor, keyboard, mouse |

| Software system: | Jingstone Metrology 2.5D CNC CAD graphic image measuring software. & 3D image & probe coaxial measuring system. |

| Measuring result output: | Word, Excel, TXT, DXF, SPC, IGES |

| Standard Accessories: | Calibration plate, measurement software, dongle, operation manual |

| Optional Accessories: | Steel instrument working table cover with OA desktop 0.7-4.5X Autozoom optic lens |